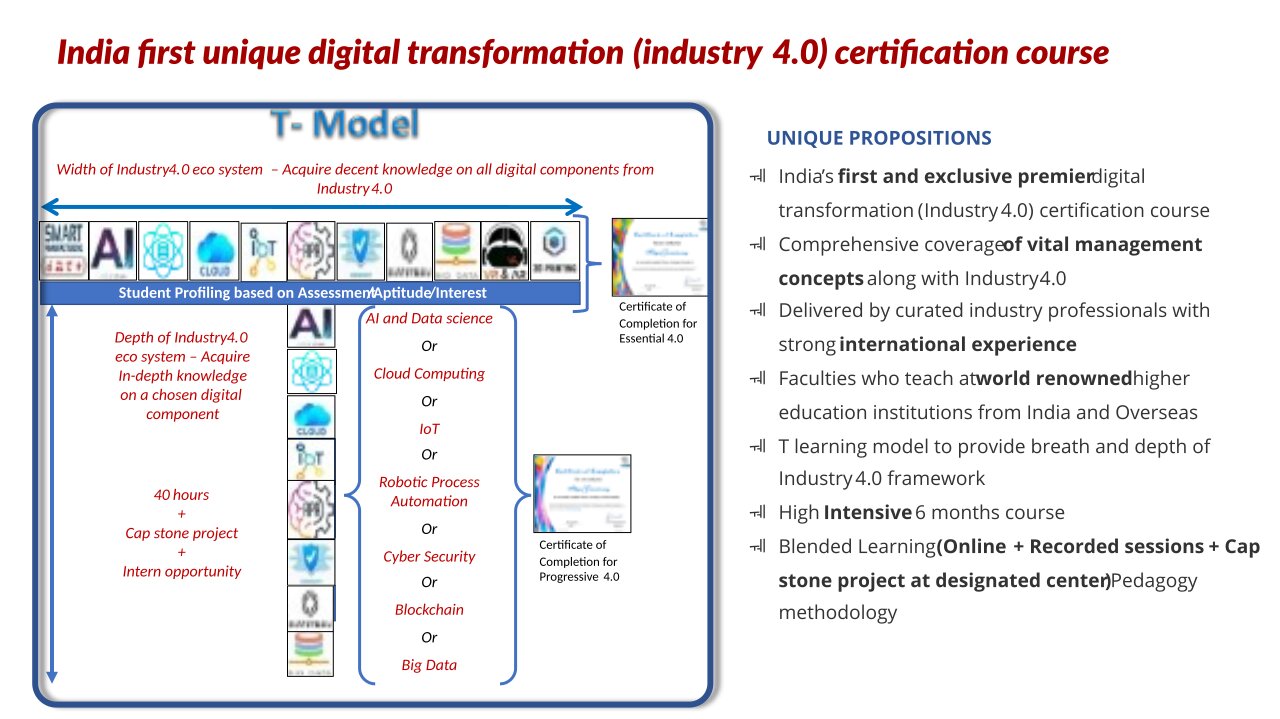

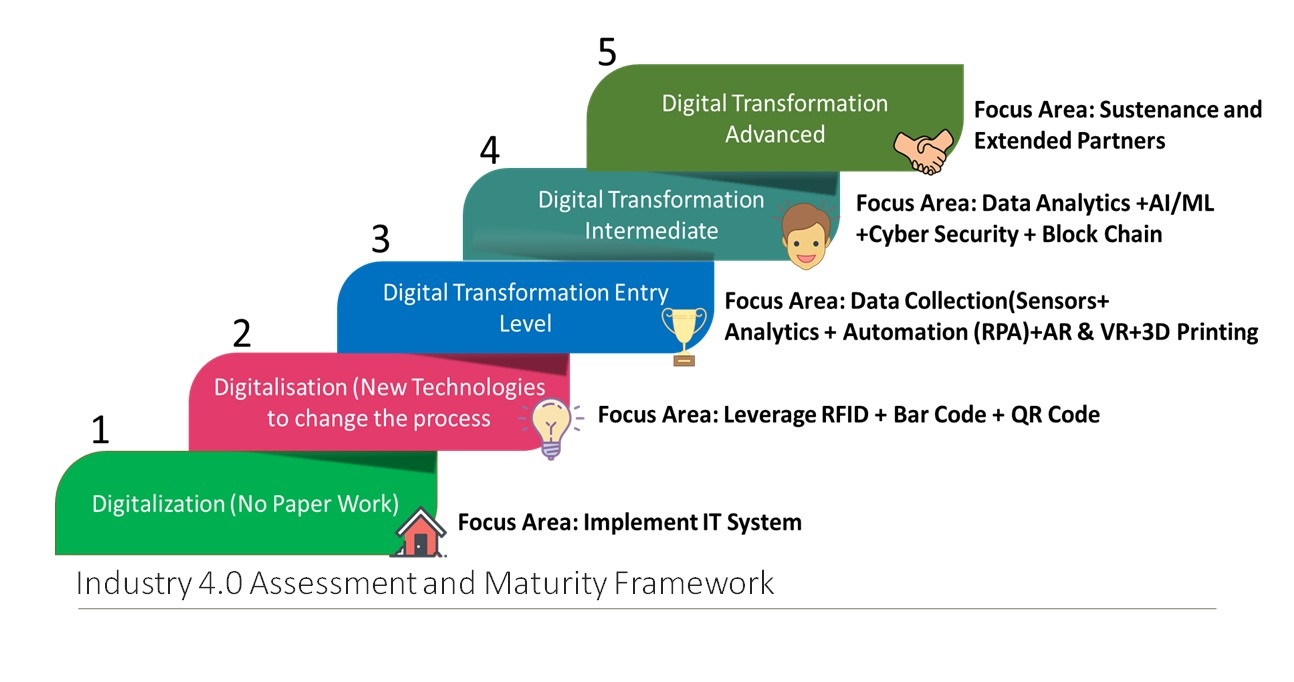

Industry 4.0 Assessment framework and Maturity Model

We do offer a scientific and proven Industry 4.0 assessment framework to assess the current capability of an organization into 9 vital organizational parameters (Leadership, strategy, business model, product portfolio, customer experience, digital operations, IT landscape, company culture, and employee skill).

For a free Industry 4.0 assessment for your organization, click the URL